A.M. Precision Machining, Inc. Company Center

170 S. Lively Blvd

Elk Grove Village, IL 60007

United States

847-439-9955

The goal of A.M. Precision Machining is to be a WORLD CLASS SUPPLIER of quality machine parts that meet, regulatory, statutory, and customer requirements for aerospace, military, oildrilling, power generation, and various other industries.

A.M. Precision Machining has developed a quality management system based on the ISO 9001:2000 and AS9100:2000 Rev. B models for quality assurance. This system has been implemented to assure a consistent approach toward achieving the defined quality objectives, which are reviewed and monitored by Executive Management. The Quality Policy is communicated throughout the organization through training, internal audits, & various postings throughout the facility.

A.M. Precision Machining, Inc. was established in 1983. For over 25 years, AMP has continued to service the aerospace industry because the complexity and trouble-shooting drives the enthusiasm of our staff. AMP is a small woman-owned and family-operated, ISO-9002 and AS-9100 certified machine shop, which provides 3, 4, and 5 axis CNC milling and turning and several EDM capabilities for aerospace, military, oil drilling, power generation, and various other industries.

Our company offers services such as assembly for turnkey products, and special processes done by recognized aerospace qualified suppliers. AMP specializes in low to medium volumes for materials ranging from aircraft aluminum to aerospace exotics such as Inconel, Titanium, Copper, Beryllium, Waspalloy, and Hastalloy. Our secondary operations include a full in-house tool room, lapping and gun-drilling.

In the 1980's, AMP assisted in the design and development of Diffusers to Rolls Royce-Allison Engine for the V-22 Osprey. And, in the early 1990's, AMP aided in the development and production of load plates for Pratt & Whitney aircraft exhaust system housing for YF-22 Joint Strike Fighter Eng# F119.

Some flight critical parts we have manufactured directly for Boeing are 15-5PH 64" long pairs of struts and chords for mounting and support of aircraft engines to the wings of Boeing 747s and various wing components for Boeing 737s and Boeing 767s, as well as various clips for the fuselage and Al-Beryllium components for Boeing Defense.

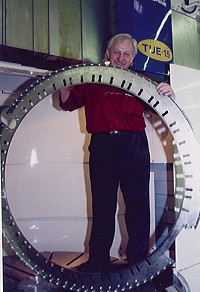

For aircraft jet engines, AMP manufactures Titanium discs for aircraft engines - 2nd stage compressor, fuel nozzles, valves, duct seals and other hydraulic components for companies such as Parker Hannifin and Goodrich. We also manufacture vanes and blades for turbine engine production and titanium discs for aircraft engines - 2nd stage compressors. We provide services for certified FAA repair stations such as the manufacture of inner and outer shroud rings for aircraft jet engines complete from Inconel and SS, including EDM of vane slots for aircraft jet engines with a size range: 24" O.D. to 42" O.D. and we have the capability to go smaller or larger

Aside from jet engine components, AMP manufactures hydraulic pistons for aircraft brakes and axial piston pumps. Our aerospace expertise also expands into helicopter components such as forged Aluminum blade grips for helicopter propellers.

Products & Services

- Engines, Engine Components, Propellers (Aerospace)

- Helicopters (Defence)

- Landing Gear / Wheels, Brakes (Aerospace)

- Machine Guns, Small Arms and Sights (Defence)

- Maintenance, Repair and Overhaul (Aerospace)

- Manufacturing, Engineering and Test Equipment (Defence)

- Military and Special Purpose Vehicles (Defence)

- Navy (Defence)

Last update by Margaret M. Kozlowski, Wed 18 Aug 2010