Ceradyne, Inc. Company Center

3169 Red Hill Avenue

92626 Costa Mesa, CA

United States

714-384-9483

Ceradyne Armor Systems

Ceradyne is a vertically integrated manufacturer of lightweight, ceramic composite armor systems for personnel, vehicle, watercraft, helicopter and aircraft applications.

Vertically integrated manufacturing includes: Powder Production, Ceramics Fabrication, Armor Fabrication, System Integration, and Ballistic Evaluation.

Ceradyne has been a leader in the manufacturing of advanced technical ceramics for ballistic applications since 1969. From the earliest application of ceramics in lightweight helicopter armoring, Ceradyne has provided innovative ballistic protection solutions that are the lightest and most durable armor systems available.

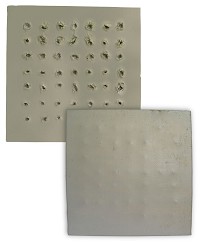

Individual Combatant Protection: Single, double and triple curve plates and multi-hit systems featuring boron carbide and silicon carbide advanced ceramics.

Special Operations Force Protection: Special operations forces currently use Ceradyne body, side and shoulder armor. Advanced protection for other vulnerable body areas including hips, legs and arms is under development.

Vehicle Armor Systems: RAMTECH2® Modular Armor utilizes a variety of advanced lightweight materials for direct application on tactical wheeled vehicles. Other modular applications include lightweight ceramic composite systems for small boat and commercial armored vehicles.

Vessel Armor Systems: DEFENDER® composite armor panels provide customized armor protection levels according to mission specific requirements. The add-on modular armor panels are highly resistant to environmental degradation and incidental damage, and include anti-corrosive attachment hardware.

Aircraft Armor Systems: Complete armor systems including ceramic armor seats, wing panels, structural components, and flooring kits for helicopter and fixed-wing applications.

Advanced Armor Technology: Patented armor technology using boron carbide and silicon carbide hot pressed ceramics, pressureless-sintered silicon carbide, silicon nitride and alumina based solutions in plate and round forms.

With vertically integrated manufacturing, state-of-the-art materials and innovative design, Ceradyne Armor Systems meet or exceed the most demanding ballistic protection requirements.

Ceradyne, Inc. (NASDAQ:CRDN)

Headquartered in Costa Mesa, California, Ceradyne Inc. is a fully integrated developer and manufacturer of advanced technical ceramic products and components for defense, industrial, nuclear, electronic, automotive and medical markets. Founded in 1967, Ceradyne has diversified its product lines to capture opportunities created by the growing demand for better materials performance. In late 2004, the company added new product lines and new markets—and one of the world's leading suppliers of starting powders for manufacturing advanced ceramics products—by acquiring ESK Ceramics of Kempten, Germany.

The unique characteristics of advanced technical ceramics—hardness, light weight, ability to withstand extremely high temperatures, resistance to wear and corrosion, low friction, and special electrical properties—offer significant advantages over traditional materials such as metals and plastics. As a result, Ceradyne continues to develop new uses for ceramics and offers a diversified line of high performance ceramic products for a wide range of markets.

Markets and Applications

Defense Military: ballistic armor protection for personnel, combat and tactical vehicles, small boats, helicopters, and fixed wing aircraft. Aerospace engine igniters, missile radomes, bushings and bearings.

General Industry: Manufacturing components for aluminum processing, silicon refining, semiconductor processing, aluminum metalizing, cast iron and super-alloy cutting. Casting/pressing/forming components for steel and aluminum casting, titanium forming, glass tempering, and thin-strip metal casting. Petrochemical parts/tools for crude oil drilling, extraction and measurement.

Neutron Absorber Materials: BORAL® Composite, BORTEC® MMC, BorAluminum™, BoroBond™, Enriched Boron, and Boron Carbide offer a full range of thermal neutron absorber materials for criticality control in wet and dry, used and fresh fuel transportation/storage applications and reactor control systems. Electronic Boron dopants and isotopes for semiconductor production, high performance parts for the electronic industry, cluster ion implantation sub systems and advanced ion source materials.

Automotive/Diesel Engine: Diesel engine cam rollers, fuel pump components and rollers cylindrical rollers for hybrid roller bearings.

Medical/Dental Medical components for diagnostic and surgical instruments. dental abutments and crowns, translucent orthodontic brackets.

Ceradyne Operating Divisions: Advanced Ceramic Operations – Costa Mesa and Irvine, California; Advanced Ceramic Operations – Lexington, Kentucky; Ceradyne Armor Systems, Inc. – Washington, D.C.; Ceradyne Boron Products LLC – Quapaw, Oklahoma; Ceradyne Canada ULC – Chicoutimi, Quebec, Canada; ESK Ceramics – Kempten, Germany; ESK Ceramics – Bazet, France; Minco, Inc. – Midway, Tennessee; Thermo Materials – Atlanta, Georgia; Tianjin Technical Ceramics – Beijing, China; SemEquip, Inc. – North Billerica, Massachusetts; Semicon Associates – Lexington, Kentucky; Vehicle Armor Systems – Wixom, Michigan.

Products & Services

- Manufacturing, Engineering and Test Equipment (Defence)

- Maritime Security (Defence)

- Personal Protection, Medical and Survival Equipment (Defence)

- Research and Development (Defence)

- Vehicle Ballistic Protection (Defence)

Last update by Patti Bass, Tue 2 Jun 2009